Comparing Hexamethylenetetramine with Other Resin Catalysts – Why InterHaven ChainTech’s Solution Excels

- Addtime: 2025-05-16 / View: 690

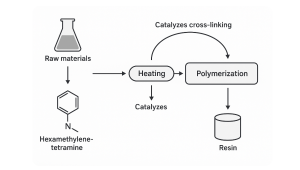

In the resin production industry, selecting the right catalyst is essential for achieving optimal curing times, product strength, and cost-efficiency. Many B2B buyers face challenges such as inconsistent product quality, extended production cycles, and increased operational costs. Hexamethylenetetramine for resin production has become a preferred choice due to its excellent performance characteristics. InterHaven ChainTech offers a high-purity hexamethylenetetramine product that outperforms other resin catalysts in reliability and efficiency.

What Makes Hexamethylenetetramine Superior in Resin Production?

Hexamethylenetetramine is a crucial chemical used as a curing agent and catalyst in phenolic resin manufacturing. Compared to other resin catalysts, it provides uniform curing, reduces residual stress in the finished product, and enhances thermal stability. These properties lead to stronger and more durable resins, essential for applications ranging from molding compounds to adhesives and coatings.

Additionally, InterHaven ChainTech’s hexamethylenetetramine is manufactured with stringent quality control to ensure consistent particle size and purity. This consistency improves resin reaction rates and minimizes defects during production, resulting in higher yield and less waste.

Performance Benefits and Cost Efficiency of InterHaven ChainTech’s Product

Choosing the right catalyst directly affects production costs and product performance. Hexamethylenetetramine from InterHaven ChainTech offers superior catalytic efficiency, which shortens curing time and increases production throughput. This efficiency translates into lower energy consumption and reduced labor costs.

Moreover, the durability of the resulting resin improves product lifespan and reduces warranty claims. Many customers have reported a 15 to 20 percent reduction in production downtime after switching to InterHaven ChainTech’s hexamethylenetetramine. Such improvements not only optimize manufacturing but also enhance the final product’s market competitiveness.

Why InterHaven ChainTech is the Leading Supplier of Hexamethylenetetramine for Resin Production

InterHaven ChainTech stands out among chemical suppliers due to its commitment to quality, innovation, and customer service. The company’s modern manufacturing facilities use advanced purification technologies that guarantee product consistency. Their experienced R&D team continuously works on refining hexamethylenetetramine formulations to meet evolving industry demands.

The company also provides tailored supply chain solutions and technical support, ensuring timely delivery and expert assistance throughout the customer journey. These advantages make InterHaven ChainTech a reliable partner for resin producers seeking to improve efficiency and product quality.

Conclusion: The Smart Choice for Resin Manufacturers

Hexamethylenetetramine for resin production remains a critical component in manufacturing durable and high-performance resins. InterHaven ChainTech’s superior product quality, consistent performance, and cost-saving benefits set it apart from competitors. For resin producers looking to optimize their processes and deliver better products to market, InterHaven ChainTech’s hexamethylenetetramine represents a trusted and innovative solution.